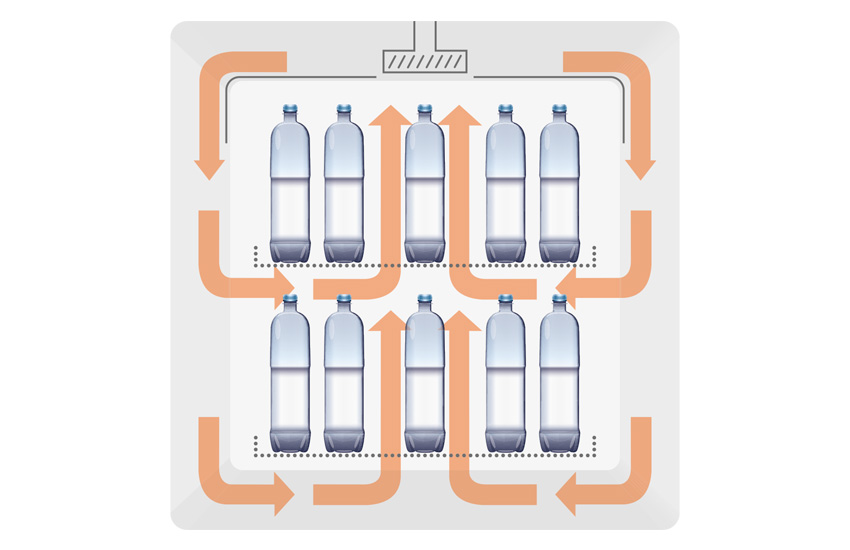

The main difference between the Ventilab® PL and the Vakulab® PL is the taller chamber that allows a fan to be built in without reducing the chamber volume. In addition, all of the equipment components necessary for sterilizing liquids in closed containers, such as a temperature probe, chamber wall, fan, and the “Closed solutions” software package, are already included as a standard feature.

H model 669

830 x 650 x 990

521

1.898 x 1.600 x 1.270

H model 969

1,130 x 650 x 990

708

1,898 x 1,600 x 1,270

Technical data subject to change without notice

The Vakulab® PL is ideally suited for sterilizing solid and porous materials, liquids in open or loosely sealed containers as well as for sterilizing infectious waste and liquids in closed containers by means of the steam/air mixture process.

The sterilizer complies with the Pressure Equipment Directive (PED) 2014/68/EU and the Machinery Directive 2006/42/EC. CE marking according to PED 2014/68/EU. The standards applied are: DIN 58951-2 Steam sterilizers for laboratory use, AD 2000 Design of Pressure Vessels and DIN EN 62304 Medical device software. Sterilization pressure vessel, double-walled, internal walls and steam jacket made from stainless steel, material no. of the internal walls: 1.4404 (AISI 316 L)/jacket: 1.4571 (AISI 316 Ti). Piping system: constructed as per DIN EN 285, steam-conducting pipes and valves made from stainless steel. All pipes are color coded and thermally insulated. Software validation according to DIN EN 62304, electrical equipment for measurement and control according to DIN EN 285.

High-tech – harnessed intelligently

The latest generation of PLC controllers enables intuitive operation, password-protected data management, and parameter-controlled free process programmability that allows all project-specific details to be individually accounted for.

Precise process control

» State-of-the-art industrial controller

» Redundant sensors for superior process reliability

» PPV system: Process Parameter Verification

» Interfaces for optimal integration

The software

» Secure and user-friendly

» Software development and validation according to DIN EN 62304 Software life-cycle processes.

» The sophisticated parameter structure provides a high level of flexibility when configuring the machine

» User management features ensure excellent access security.

Custom machine configuration

» Continuous monitoring of all measured values

» Precise regulation of the actuators

» Barcode reading system with automatic program selection (optional)

» Operator IDs and user management

» Autostart for automated program sequences, such as vacuum test, heating (optional)

» ISA – Intelligent Service Advisor

» Active P&ID diagram (optional)

Download the brochure and find out more about the Ventilab® PL

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service