The Uniclean® PL II 30 single-chamber machine has been specially designed for areas in which it is not possible to house a large-chamber WD for reprocessing sterile goods containers. The 2 in 1 tandem chamber can reprocess up to 8x 1 StU sterile containers and up to 12x ½ StU sterile containers or up to 36 DIN instrument trays in one cycle. The benefit of the tandem chamber design lies in the doubled reprocessing capacity with the same minimal space requirements (width) compared to the Uniclean® PL II 15 of the same series. The Uniclean® PL II 15 can also reliably reprocess complex instruments such as DaVinci robotic instruments.

36

810 mm

640 x 648 x 1,640

680 liters

1,000 x 1,950 x 1,778

Technical data subject to change without notice

Under the name “concept 15.30”, the MMM Group offers optimized solutions for a high reprocessing capacity in a small space. The combination of a Uniclean® PL II 15 machine for 18 DIN trays and a Uniclean® PL II 30 machine for 36 DIN trays opens up new solutions for designing the room layout and optimizing the workflow. The two machines combine perfectly and can be installed side-by-side to cater for the specific situation on site. Synergy effects are achieved with the devices coming from the same product family (same racks, transport trolleys, roller conveyors and spare parts), which increases efficiency in your RUMED. The Uniclean® PL II series has been developed for the thorough reprocessing of large quantities of medical devices, such as general surgical and MIS instruments, anaesthetic materials, ophthalmological instruments, containers, receptacles, bowls, basins, OR shoes and other utensils.

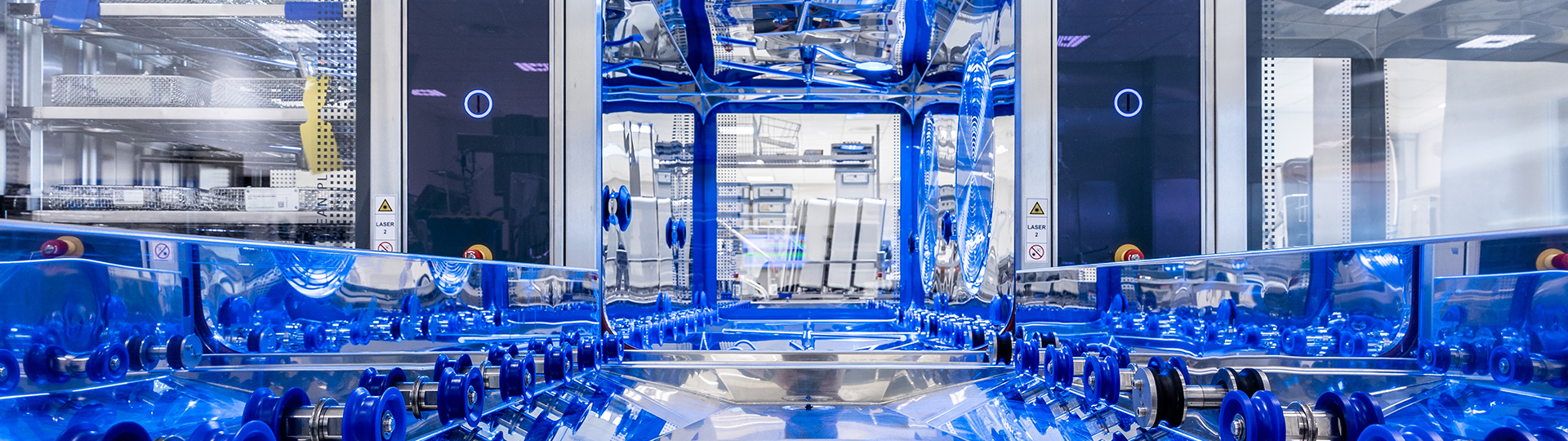

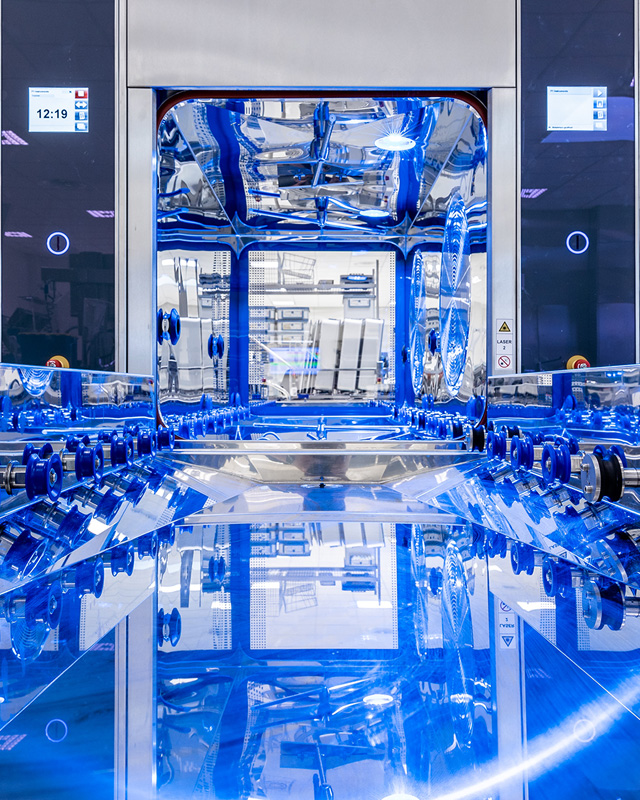

Light and light effects not only have a proven beneficial effect on humans but also increase the quality and pleasantness of the workplace. The “Halo” LED control panel developed by MMM provides a perfect interplay of ambiance and function. The “Halo” light effect in various status colors reflects off the stainless steel surface and gives the MMM washer-disinfector a stylish appearance. The vertically arranged operating panel with the MMM Smart HMI promises intuitive and reliable operator guidance.

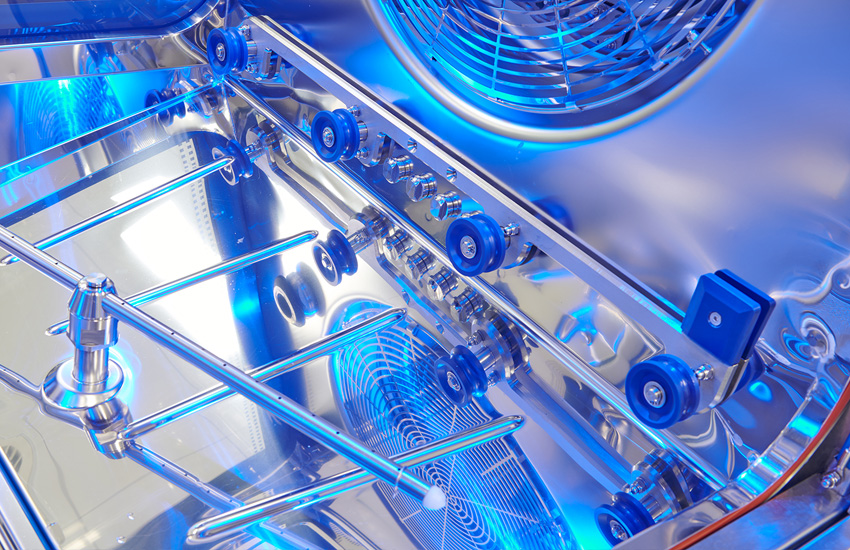

The 8D cleaning system developed by MMM creates a full-coverage spray pattern that acts from above and below. The pump pressure, which is optimally matched to the water volume and process chemicals, distributes the water evenly to all four consumers (two rotary arms in the chamber, two JANUS rack connections).

The cleverly devised cleaning geometry and the interplay between the machine and rack allows all external and internal surfaces of the goods being treated to be optimally reached and wetted.

The two-stage high performance drying system consists of two heating elements, a fresh air fan above a HEPA filter, and a fan that is mounted laterally in the chamber. Thanks to the horizontally whirling air current, the hot air reaches all rack levels directly. The high level of hot air circulation in the chamber allows the existing heat to be stored and greatly accelerates the drying process.

Hygienically impeccable: The integrated air turbine and the heating elements are also cleaned and disinfected during each process.

Download the brochure and find out more about the Uniclean® PL II 30

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service