Specially designed to sterilize sensitive or heat sensitive medical devices, the high quality Hyper LTS® 150 offers unique technologies at a high safety level and meets the highest requirements. With intuitive control and a user-friendly interface, the Hyper LTS® 150 is easy to use and operate.

Hyper LTS 150-1

1

450 x 450 x 760

150

3,6

1,612 x 700 x 891

Hyper LTS 150-2

2

450 x 450 x 760

150

3.6

1,612 x 700 x 925

Technical data subject to change without notice

User-friendly Hyper LTS® H2O2 technology with low power and energy consumption. The hydrogen peroxide used during the gas plasma phase decomposes into water and oxygen for safe release into the environment. H2O2 sterilization provides user safety and is environmentally friendly

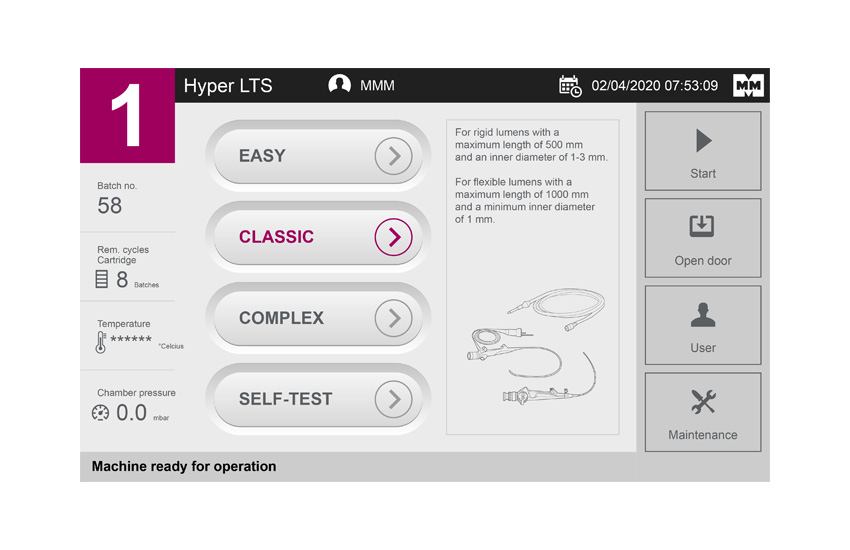

The human/machine interface (Smart HMI) is one part of MMM’s concept for simplifying the work of operating personnel. All process-relevant information—such as the device status, process steps, values, and process graphs—can be read at a glance on the display.

Used for sterilization of medical devices to achieve a sterility assurance level (SAL) of 10-6.

MMM Hyper LTS® 150 cartridge

The sterilization process of the Hyper LTS® 150 consists of two half cycles and a plasma phase

at the end of each half cycle to safely achieve a Sterility Assurance Level (SAL) of 10-6.

Environmentally friendly

The by-products after sterilization are water and oxygen. Sterilization uses hydrogen peroxide, a powerful but safe disinfectant that leaves no harmful residues or by-products. This contributes to environmental protection as well as to user-friendliness and safety.

Low temperature sterilization

The process temperature keeps lower than 60° C (during holding time between 55 and 60° C) and the cycle times are less than 1 hour (EASY, CLASSIC, COMPLEX). This gentle method ensures less heat stress to the materials of the medical devices.

Safety

The H2O2 plasma sterilizer is user friendly as the main sterilizing agent is very safe. Due to a redundant safety system consisting of a plasma inactivation phase during each half cycle and an integrated catalytic converter on the outlet of the vacuum pump, the remaining H2O2 if effectively cracked into non-toxic residues (water and oxygen).

Cycle time and economic efficiency

Die kurzen Zykluszeiten erlauben mehr Kapazität. Somit ist weniger Bestand an teuren Instrumenten erforderlich und der wirtschaftliche Nutzen für die Gesundheitseinrichtung ist insgesamt höher.

The short cycle times increases turnover of instruments. Thus less inventory of expensive instruments is needed and a higher economical benefit for the healthcare facility is reached.

The modern industrial PLC control offers many possibilities and high capacity. MMM uses the same control systems in its steam sterilizers and washer-disinfectors, enabling safe and user-friendly operation.

General instruments

» Scissors, scalpels, saws

» Forceps, clamps

» Retractors, surgical hooks

» Knives, blades, trocars

» Batteries

» Sterilization cases

» Instrument trays

Rigid endoscopes and accessories

» Laryngoscopes

» Arthroscopes

» Laparoscopes

» Surgical telescopes

» Laparoscopic instrument sets

» Robotic instruments

» Cannulas

» Trocar sheaths

Flexible endoscopes and accessories

» Bronchoscopes

» Hysteroscopes

» Cystoscopes

» Ureteroscopes

» Cameras

» Light cords

Electrical devices

» Ultrasonic handpieces

» Power drills

» Ultrasound probes

» Transducers

Download the brochure and learn more about the Hyper LTS® 150

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service