If a supply of pure steam is not available on site, your sterilizer can be operated together with an MMM steam-to-steam generator. No matter how your facilities are laid out, the steam-to-steam generator can be installed beside, above or away from the steam consumer. The steam-to-steam generator can be conveniently operated via the operating panel on the sterilizer. The Duotherm II also offers the option of converting heating steam to pure steam in facilities with a separate heating steam supply. The compact design of the Duotherm II has many advantages.

Technical highlights:

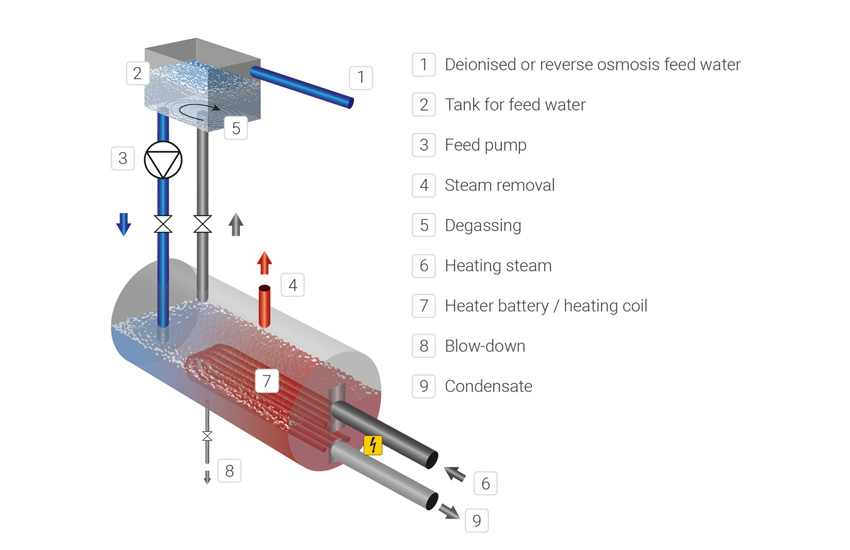

The Duotherm II steam-to-steam generator is in a class of its own thanks to the high quality of the pure steam and its long service life. For example to keep the proportion of non-condensable gases in the sterilization steam as low as possible, the boiler feed water is thermally degassed in a process controlled and monitored by a temperature sensor. The quality of the boiler water is maintained at a constant high level by automatic blow-down.

The blow-down can optionally be conductance-controlled. This completely eliminates the possibility of performance being affected due to deposits and corrosion. The service life of the boiler components is extended, and instruments are protected during sterilization. High performance is guaranteed with optimal sterilization steam, the required steam pressure is reached quickly, and the long service life of the parts means that maintenance costs are kept low. Even if the heating steam pressure is low, the Duotherm II is an ideal steam-to-steam generator: It can be ready for use and supply pure sterilizing steam starting at a heating steam pressure of just 4 bar.

Download the brochure and find out more about the Duotherm II

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service