The hygienic design and customer-specific special features of the Vakulab® HL handle the demanding tasks involved in the production of sterile materials, such as solutions or filled syringes, as well as those encountered in production-related areas where the sterilization of fermenters, machine parts, clean room garments, filters, etc. calls for individual solutions.

H model 669

710 x 650 x 990

460

1.918 x 1.900 x 1.360

H model 969

1,000 x 650 x 990

644

1,918 x 1,900 x 1,360

Technical data subject to change without notice

Suitable for sterilizing solid and porous materials using the pre-vacuum process or pulsed vacuum process following by drying. Liquids in open or loosely sealed containers using the pre-vacuum process.

Liquids in tightly sealed containers made from glass or heat-resistant material using the steam/air mixture method (SAMM) (only with the steam/air mixture process option). Infectious materials (only with the Exhaust air filter feature). The sterilizer complies with the Pressure Equipment Directive (PED) 2014/68/EU and the Machinery Directive 2006/42/EC. CE marking according to PED 2014/68/EU. The standards applied are: DIN 58950, AD 2000 Design of Pressure Vessels and DIN EN 62304 Medical device software.

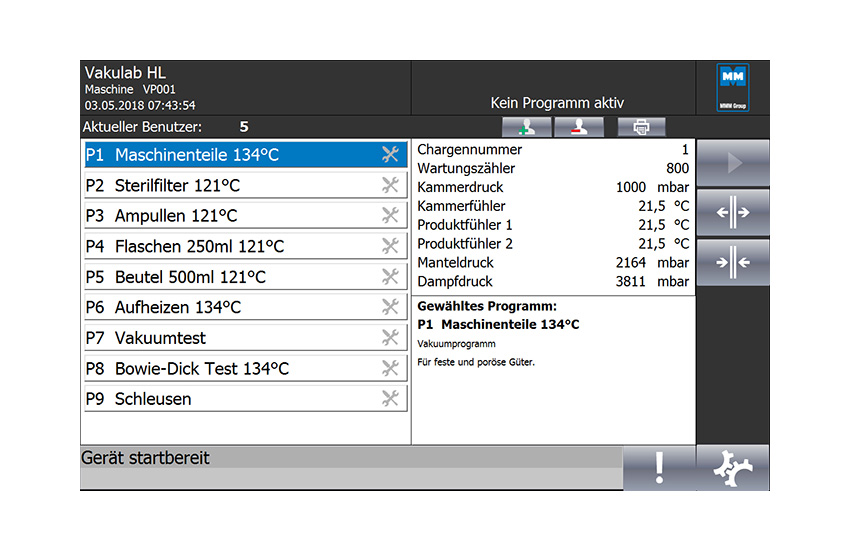

High-tech – harnessed intelligently

Combined with MMM’s SiSoft control software, the latest generation of Simatic controllers enables intuitive operation, password-protected data management, and parameter-controlled free process programmability that allows all project-specific details to be individually accounted for.

Precise process control

» State-of-the-art industrial controller

» Redundant sensors for superior process reliability

» PPV system: Process Parameter Verification

» Interfaces for optimal integration

The software

» Secure and user-friendly

» Software development and validation according to DIN EN 62304 Software life-cycle processes.

» The sophisticated parameter structure provides a high level of flexibility when configuring the machine

» User management features ensure excellent access security.

Custom machine configuration

» Continuous monitoring of all measured values

» Precise regulation of the actuators

» Barcode reading system with automatic program selection (optional)

» Autostart for automated program sequences, such as vacuum test, heating (optional)

» Versioning and release of programs (optional)

» Active P&ID diagram (optional)

» External communication interfaces, e.g., via Profinet (optional)

Conformity with 21 CFR Part 11

» User management

» Data archiving with checksum

» Audit trail

Download the brochure and find out more about the Vakulab® HL

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service