With us, you receive more than just repairs. From commissioning and validation right through to maintenance and ongoing support – you can rely on us.

We offer a comprehensive portfolio of services in the proven MMM quality and solutions perfectly tailored to your needs. In this way we ensure the high availability of your systems and extend their service life, because we operate on the principle of life cycle management and support every machine for as long as we have the knowledge and the necessary spare parts.

With MMM, you will always have a reliable partner at your side.

A regular thorough check of your machines ensures their safety and trouble-free operation. Using inspection reports as per manufacturer requirements, we document every test item and thereby create the necessary transparency. And because prevention is important, the assessment intervals are adjusted according to the level of utilization. We would be happy to put together a smart inspection package for your needs.

A regular thorough check of your machines ensures their safety and trouble-free operation. Using inspection reports as per manufacturer requirements, we document every test item and thereby create the necessary transparency. And because prevention is important, the assessment intervals are adjusted according to the level of utilization. We would be happy to put together a smart inspection package for your needs.

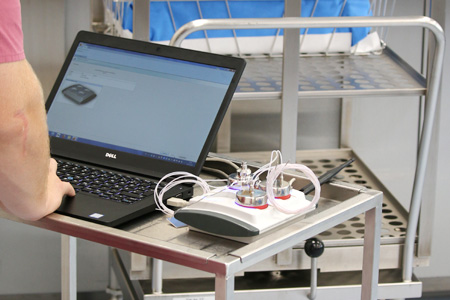

With regular servicing intervals perfectly tailored to the level of utilization, we will keep your equipment in good working order. This enables us, for example, to exchange components with a limited service life on time with suitable maintenance kits for each series. In conjunction with the RUMED360® communication interface, it is also possible to dynamically control and monitor the servicing interval. This ensures plannable and user-optimized servicing work and keeps your equipment in good working order.

In the event of a fault, it is important to act fast to keep downtimes as short as possible and to quickly restore the availability of the defective machine. Our worldwide network of qualified technicians ensure a speedy repair. This can, if necessary, be supported by remote analysis to expedite the repair.

In the event of a fault, it is important to act fast to keep downtimes as short as possible and to quickly restore the availability of the defective machine. Our worldwide network of qualified technicians ensure a speedy repair. This can, if necessary, be supported by remote analysis to expedite the repair.

The availability of spare parts is essential for maintaining the operability of medical devices. We look after you and your products as part of our life cycle management. This means: We will support you for as long as the knowledge and the required original spare or wear and tear parts are available for your products. We also store some no longer available components for older machines. Our employees in spare parts logistics are experts in their field and are familiar with each of the more than 20,000 parts. They support you with your first time fix strategy and organize the dispatch from our central warehouse – within 24 hours in 95% of cases.

The availability of spare parts is essential for maintaining the operability of medical devices. We look after you and your products as part of our life cycle management. This means: We will support you for as long as the knowledge and the required original spare or wear and tear parts are available for your products. We also store some no longer available components for older machines. Our employees in spare parts logistics are experts in their field and are familiar with each of the more than 20,000 parts. They support you with your first time fix strategy and organize the dispatch from our central warehouse – within 24 hours in 95% of cases.

Technology is constantly improving – your equipment should too. To ensure your machines are always state of the art, we carry out regular enhancements and updates/upgrades. New functionality can be integrated into our existing product range at any time. Using retrofit kits, even older machine series can be updated to the current state of the art. We stay up-to-date for you and keep your systems current.

Technology is constantly improving – your equipment should too. To ensure your machines are always state of the art, we carry out regular enhancements and updates/upgrades. New functionality can be integrated into our existing product range at any time. Using retrofit kits, even older machine series can be updated to the current state of the art. We stay up-to-date for you and keep your systems current.

Saving resources and protecting the environment is important to us. That is why we use programs specifically tailored to our machines to increase efficiency. Recycling tanks, energy recovery systems and other hardware can be retrofitted into the overall system. Furthermore, RUMED360® enables processes and workflows to be optimized for more user-friendliness, efficiency and profitability.

Saving resources and protecting the environment is important to us. That is why we use programs specifically tailored to our machines to increase efficiency. Recycling tanks, energy recovery systems and other hardware can be retrofitted into the overall system. Furthermore, RUMED360® enables processes and workflows to be optimized for more user-friendliness, efficiency and profitability.

Our experienced validators will advise and support with validating and requalifying your machines or perform this for you. Of course while adhering to the country-specific requirements on cleaning and disinfection, packaging and sterilization.

Our experienced validators will advise and support with validating and requalifying your machines or perform this for you. Of course while adhering to the country-specific requirements on cleaning and disinfection, packaging and sterilization.

Our experts also take care of calibrating and/or adjusting measurement chains and sensors and perform safety inspections based on the current Pressure Vessel Directive as well as electrical safety checks.

RUMED360® are software applications that make your everyday work in the RUMED easier and safer. Digitalization has established itself as an integral and indispensable part of healthcare for some time now. In the modern working environment of a RUMED, process monitoring and digital documentation are important and essential components of an almost paperless working life. The resultant process and workflow optimization brings with it greater profitability, efficiency and safety. It is also generally possible to retrofit machines/installations already available in the market without significant effort or expense.

RUMED360® are software applications that make your everyday work in the RUMED easier and safer. Digitalization has established itself as an integral and indispensable part of healthcare for some time now. In the modern working environment of a RUMED, process monitoring and digital documentation are important and essential components of an almost paperless working life. The resultant process and workflow optimization brings with it greater profitability, efficiency and safety. It is also generally possible to retrofit machines/installations already available in the market without significant effort or expense.

German Customer Service: 01805 666 112*

Email: service@mmmgroup.com

* 14 ct./min. from a German landline, prices for mobiles may vary

MMM Group

Semmelweisstraße 6

82152 Planegg/Munich

Germany

Costumer Service